How Systems Technology, Inc. Is Defining the Feel of Next-Generation Rotorcraft—and Why Active Inceptor Research Matters

When a test pilot calls a rotorcraft “precise,” “predictable,” and “stable,” they’re describing something engineered—not imagined. That “feel” is the product of control laws, inceptor force-feel shaping, and the underlying pilot-vehicle dynamics.

As rotorcraft progressively adapts fly-by-wire technology, eVTOL developers embrace novel control concepts, and UAS platforms shift toward optionally piloted control philosophies, getting inceptor tuning right has become both more critical and more complex.

For decades, Systems Technology, Inc. (STI) has been the quiet authority behind handling qualities, control-law development, and inceptor behavior. And recent research—including the Vertical Flight Society paper “Handling Qualities Evaluations of Active Inceptors with Varying Force/Feel Characteristics” — reinforces a truth STI has long understood: inceptor tuning fundamentally shapes rotorcraft performance.

Why Inceptor Tuning Is Now a Strategic Requirement

Active, electronically controlled inceptors give designers unprecedented control over breakout forces, stiffness gradients, damping and inertia, mode-dependent force feedback (hover, cruise, automation), soft stops, detents, and haptic guidance, and envelope-protection cueing.

The VFS study shows that force-feel variations directly influence pilot workload, precision and aggressiveness, stability margins, PIO susceptibility, and handling qualities ratings from ADS-33 tasks.

The takeaway: inceptor feel must be engineered – not assumed.

That’s where STI excels.

How STI Engineers Superior Inceptor Feel

- Mission-Centered Handling Qualities Requirements

Every mission demands its own feel. SAR hover, autonomous cargo lifts, steep approaches – each requires distinct cues and workload expectations.

STI translates mission intent into measurable requirements using deep experience in:

- ADS-33E

- MIL-STD-1797

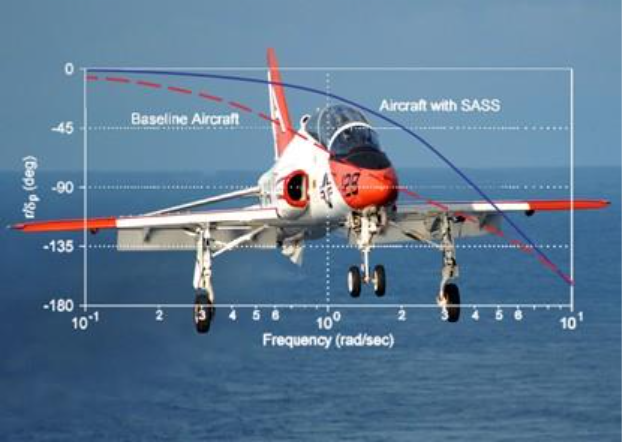

- Equivalent-system bandwidth analysis

- Workload prediction

- Pilot-vehicle system modeling

- Engineering the Force-Feel Profile

STI helps OEMs mathematically shape the inceptor’s force-feel signature, including:

- Breakout and detent forces

- Stiffness-versus-displacement characteristics

- Frequency-dependent damping

- Soft-top shaping

- Haptic cues for automation and envelope limits

This is STI’s hallmark: integrating biomechanics, human factors, and control-law response into a coherent, intuitive feel.

Mapping the Inceptor to the Control Laws

A perfect force-feel profile is only effective if the aircraft’s response matches the pilot’s expectations.

STI harmonizes inceptor dynamics with control laws spanning:

- ACAH

- TRC

- Rate-command/attitude-hold

- Hybrid and autonomous modes

- eVTOL-specific envelopes

This closed-loop mapping is where programs succeed—or encounter PIOs and MTE failures.

Simulation-Based Tuning

Long before first flight, STI uses high-fidelity simulation to analyze:

- Pilot/vehicle dynamics

- Sensitivity to natural frequency and damping

- Predicted HQ ratings across MTEs

- Hover and low-speed workload

- Control-law bandwidth and phase interaction

Flight-Test and Certification Support

In flight test, STI helps OEMs:

- Build efficient test matrixes

- Tune based on qualitative pilot feedback + quantitative metrics

- Validate hover, low-speed, and high-speed handling qualities

- Document compliance

- Address transitions, automation modes, and degraded conditions

This is where decades of handling-qualities heritage pay off.

Why OEMs Turn to STI

- 60+ years shaping the handling-qualities discipline

- Deep, proven expertise with active inceptors

- Tailored for modern eVTOL, rotorcraft, and pilot-optional UAS missions

When feel matters—and it always does—STI is the partner that ensures it’s engineered, measurable, and repeatable.

Looking Ahead: Adaptive Feel and Human-Automation Teaming

Active inceptors are quickly evolving into intelligent, cooperative interfaces. They are becoming:

- Mode-adaptive

- Automation-aware

- Haptic-communicative

- Dynamically reconfigurable

They’re no longer just sticks—they’re part of the aircraft’s cognitive system, managing workload, enforcing boundaries, cueing transitions, and enabling human-automation teamwork.

STI is already pushing this frontier, leveraging decades of human-factors and handling-qualities research to help OEMs get the next generation right.

Closing Thoughts

The VFS paper “Handling Qualities Evaluations of Active Inceptors with Varying Force/Feel Characteristics” underscores what STI has long addressed: variations in force-feel profoundly affect handling qualities. Creating the right feel is a quantitative challenge grounded in biomechanics, pilot-vehicle dynamics, software control laws, and rigorous flight-test data.

Systems Technology, Inc. Brings all these disciplines together to help OEMs build rotorcraft, eVTOL, and UAS platforms that don’t just meet performance requirements—they feel exactly the way pilots intend.

About Systems Technology Inc.: Systems Technology Inc. (STI) is a technology company at the forefront of innovation, specializing in aviation and simulation solutions. With a mission to advance safety and efficiency in aviation, STI develops cutting-edge technologies to meet the evolving needs of the aerospace industry.